AM 400

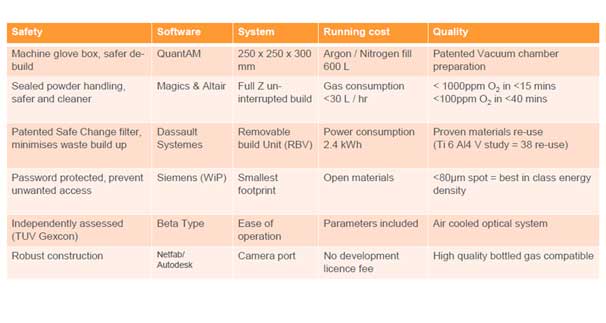

The Renishaw AM 400 is the latest development of the Renishaw AM250platform. It features the most recent system updates including a larger SafeChange™ filter, improved optical control software, revised gas flow and window protection system and a new 400 W optical system which gives a reduced beam diameter of 70 µm. The system build volume is 250 mm × 250 mm × 300 mm.

Existing 200 Watt material files for the AM250 system are directly transferable to the AM 400.

AM 400 is equipped with the features of the existing AM250, such as open materials parameters, small factory footprint, class leading inert atmosphere and low gas usage, with the added advantage of the PlusPac upgrade as standard.

Flexible material use and ease of changeover

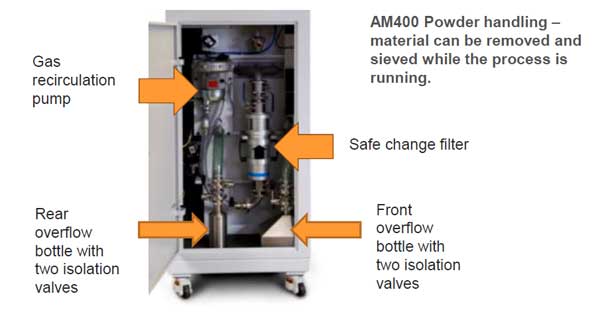

The AM 400 features an external powder hopper with valve interlocks to allow additional material to be added whilst the process is running. It is possible to remove the hopper for cleaning or to exchange with a secondary hopper for materials change, using the universal silo lift. This means that multiple material types can be interchanged on the AM 400 platform with relative ease. The powder overflow containers are outside the chamber and have isolation valves so that unused materials can be sieved and reintroduced to the process via the hopper while the system is running.

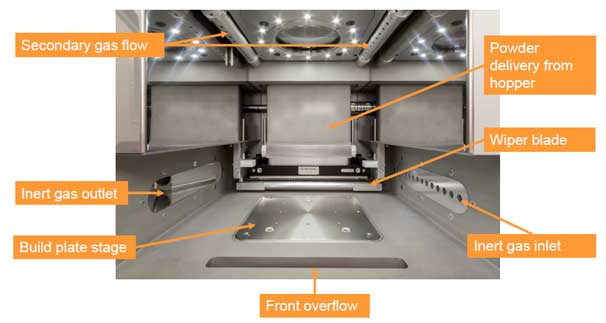

Build chamber

Powder handling – Overflow bottle

AM system overview

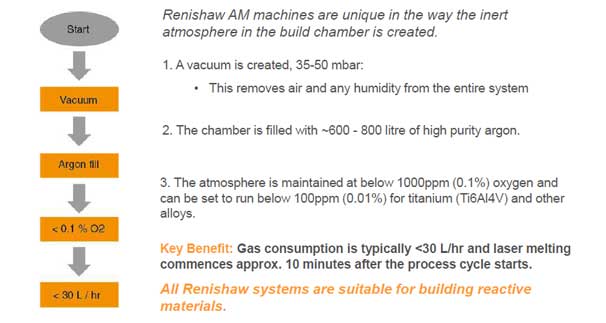

Class leading inert atmosphere genration

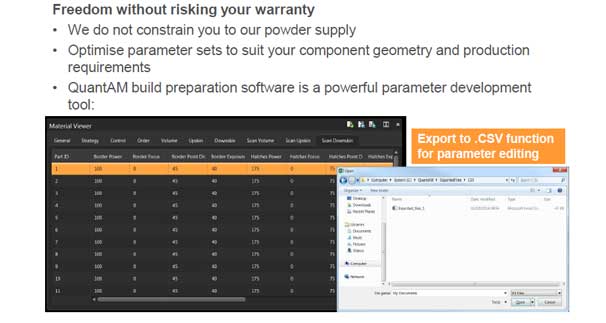

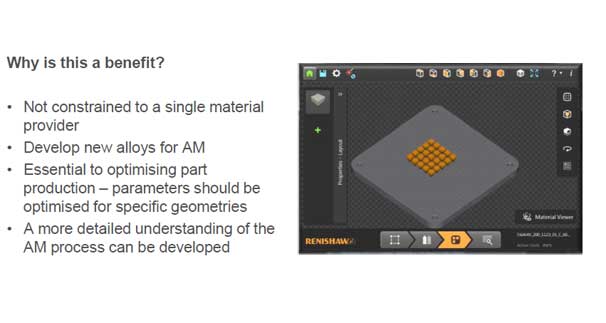

Open material parameters

Open material parameters

Class leading AM400 system features summary

Renishaw AM benefits & advantages over competitors

1.Ability to achieve a 100ppm O2 atmosphere through gas purging cycle.

a.Initial Low volume of Argon required to achieve <1000ppm or <100ppm O2 atmosphere.

b.Typically, this should be 600 liters or less to achieve <1000ppm.

2.Gas to be supplied in industry standard pressurized bottles.

3.Short preparation time to achieve <1000ppm or <100ppm O2 atmosphere before processing. Typically, this should be generated with accelerated vacuum technique followed by back flooding of the chamber to achieve <1000ppm O2 within 8 minutes of startup.

4.Capability of processing Titanium alloys at under 10ppm O2 atmosphere.

5.Ability to load new material whilst the machine is processing. The system should have the ability to load and unload powder into metal flasks under inert gas atmosphere without interrupting the machine process.

6.Open parameter access for process development. To enable the user to experiment with own melting strategies and materials. To be fully supported with in depth training on the methodology of designing experiments in order for the best outcome in the shortest possible timeframe.

7.Powder delivery with user serviceable compliant wiper blade to greatly reduce likelihood of build crashes when developing process parameters.

8.Running costs

a.Power – Low electrical power consumption rate 1.6Kw/H.

b.Single phase, 230V, 16Amp, electrical supply to ensure lowest possible running costs

c.Gas consumption – typical hourly rate of use to be 10 liters or less ensuring lowest possible running costs

9.25 μm and 50 μm layer thickness parameters available for standard materials.

10.Ability to run reactive materials as standard.

11.Touchscreen HMI interface with user level control.

12.Offline file preparation can be completed during process

13.Platform heating to 170oC

14.Z axis accuracy +/-2μm over 300 mm travel

15.Integrated powder level sensor with build pause capability at low level

16.Removable powder silo which can also be used for powder specific storage

17.Welded Stainless Steel construction main chamber with vacuum de-gas and argon refill for maximum atmosphere purity.

18.Upper door with Laser safe viewing window and glove box access to the main process chamber. Enables removal of powder from the build chamber before opening door. Lower access door for scheduled cleaning and servicing.